One of the UK`s Leading Profile Bending Companies

We are a UPVC Profile Bending Company & specialist manufacturers of Conservatory Gable & Raked End frames, Gothic Arches, True Arches, Circles, Arched Doors and much more…

Hundreds of UPVC Shaped frame designs to choose from...

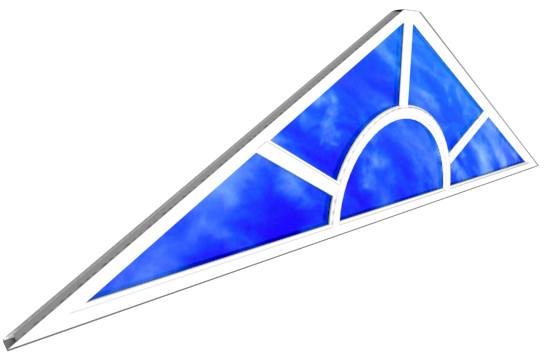

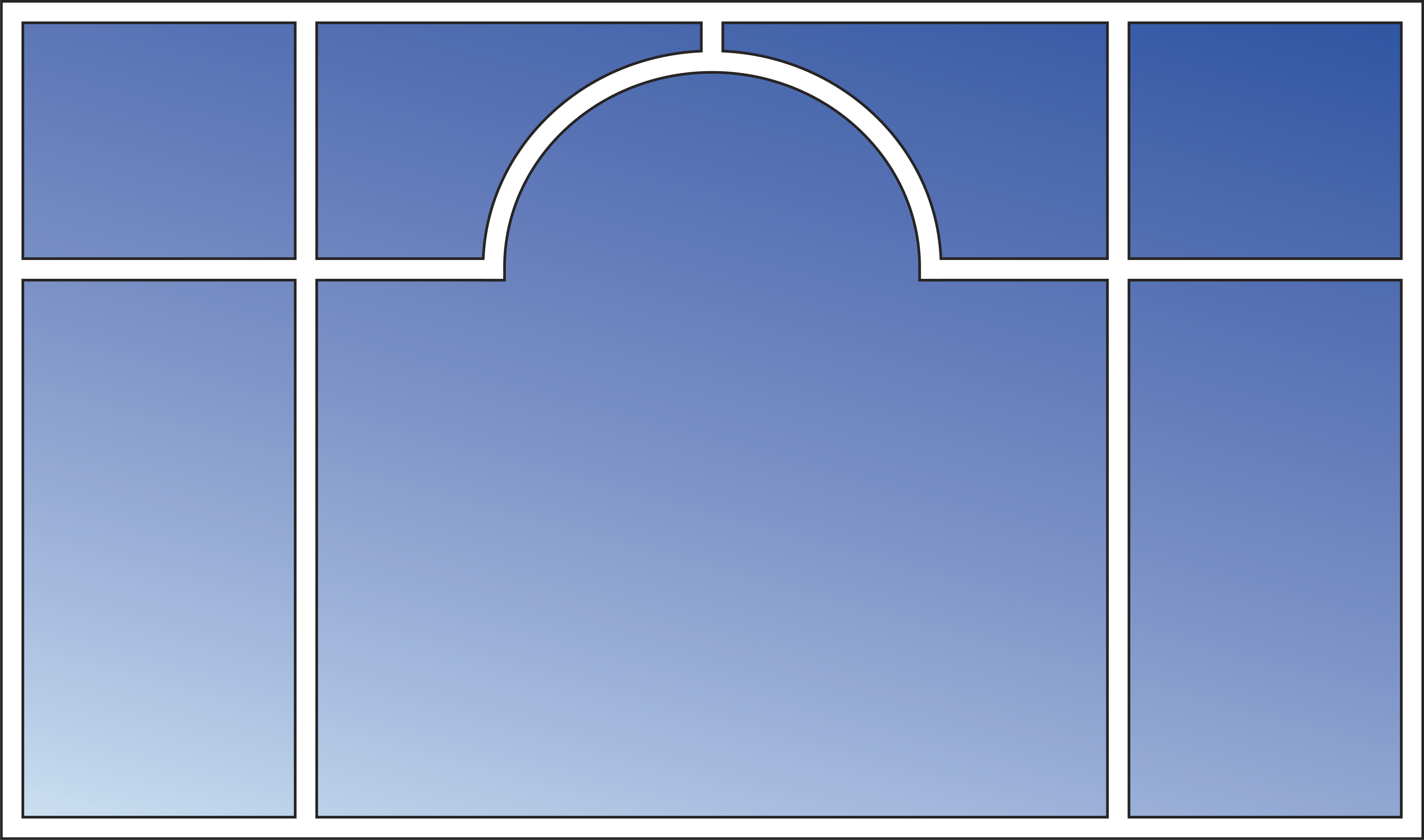

Gable Frames

38 Set designs of Conservatory Gable Frames as standard and any other bespoke designs you can think of.

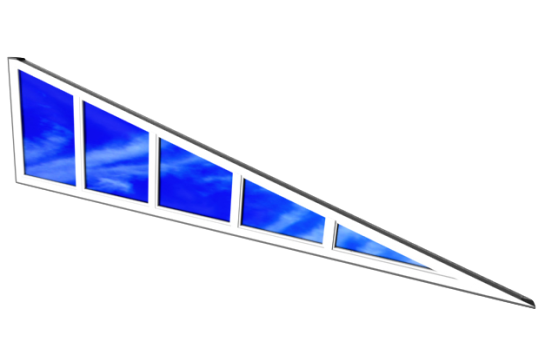

Raked Frames

8 Set designs of Conservatory Raked End Frames as standard and any other bespoke designs you can think of.

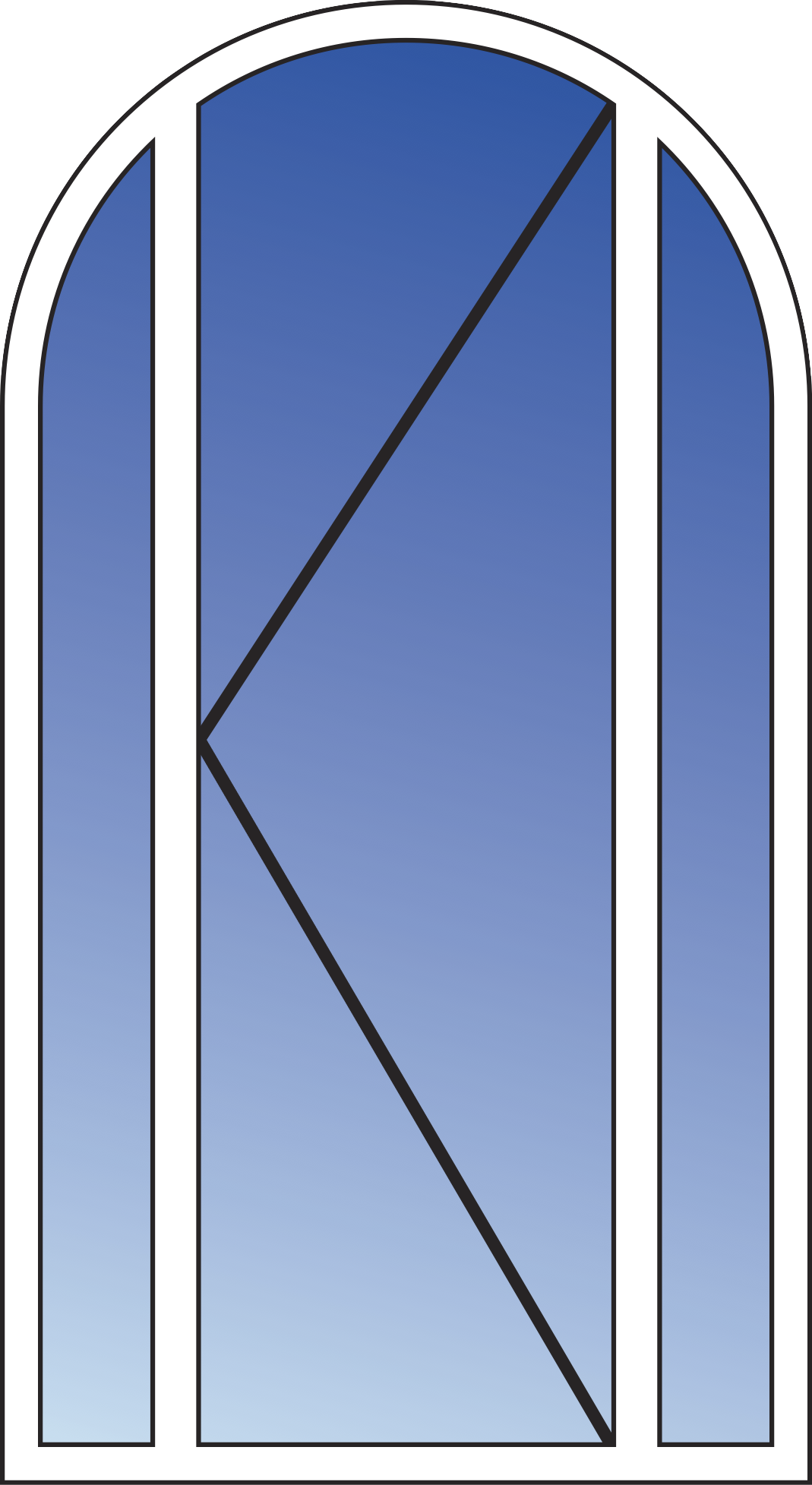

Arched Doors

31 Set designs of UPVC Arched Doors as standard and any other bespoke designs you can think of.

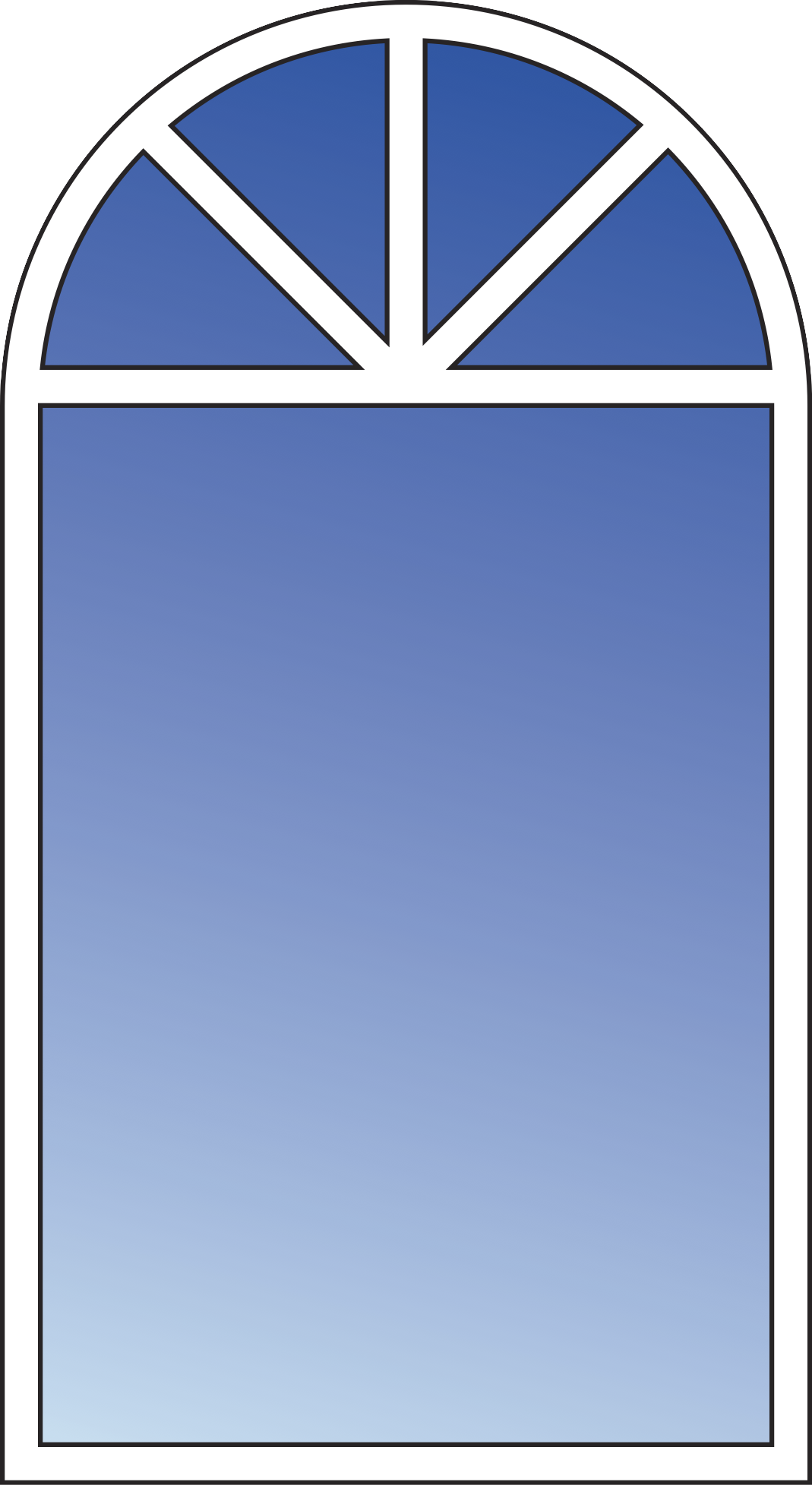

True Arches

24 Set designs of UPVC True Arches as standard and any other bespoke designs you can think of.

Gothic Arches

16 Set designs of UPVC Full Gothic Arches as standard and any other bespoke designs you can think of.

Half Gothic Arches

6 Set designs of UPVC Half Gothic Arches as standard and other bespoke designs you can think of.

Circular Windows

7 Set designs of UPVC Circular Windows as standard and any other bespoke designs you can think of.

Various Polygons

5 Set designs of UPVC Polygon Designs as standard and any other bespoke designs you can think of.

Other Curves

3 Set designs of UPVC Other Curves as standard and any other bespoke designs you can think of.

Semi Circles

12 Set designs of UPVC Semi Circles as standard and any other bespoke designs you can think of.

Bespoke Square Designs

Various Bespoke Square Frame Designs are possible, almost anything you can think of.

Get the latest news..

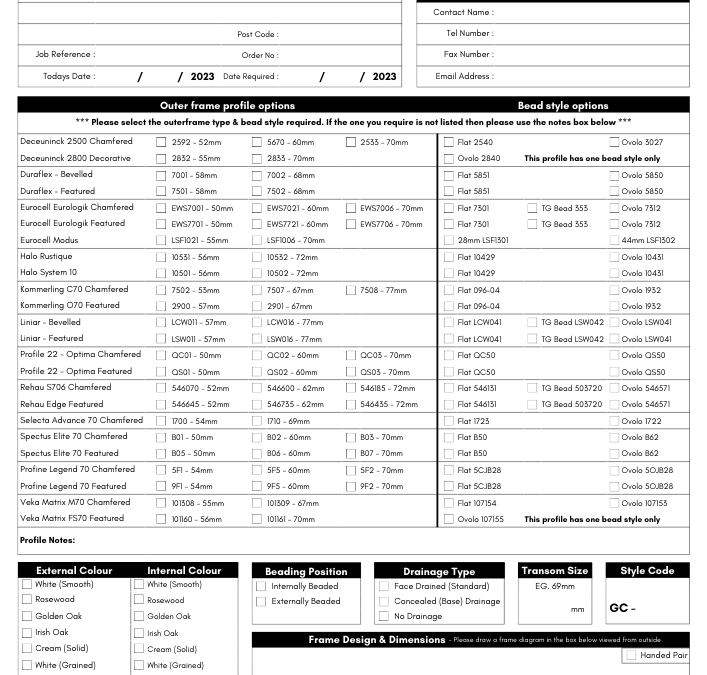

NEW 2023 Order / Quotation Forms

We have been working hard behind the scenes to complete 2 updated Order Forms for 2023. The new forms are available to download now and are even simpler than their previous counterparts to work off....

Replacement UPVC Window Beads

Need to replace some broken bead ?

- Over 80 Different Beads in Stock in a range of colours

- Supplied square cut in 1000mm or 2000mm lengths

- Delivered via carrier anywhere in the UK Mainland *

* = Carriage charges apply. Bead orders must be completed through the online shop.

Download some of our simple forms

We make Pricing & Ordering Shaped Frames as simple as childs play with our unique “10 Second Pricing Guides” & Order Forms…

Gable & Rake

Quote / Order Form

![]()

Download Here

Other Shapes

Quote / Order Form

![]()

Download Here

Profiles We Stock

Chart

![]()

Download Here

Gable & Rake

Brochure

![]()

Download Here

Gable & Rake

Showroom Poster

![]()

Download Here

Read some of our customer testimonials…

“We have used GableCraft for many years and would happily recommend them, they cover a massive range of products, are great quality and even better service.”

“The level of service we receive from GableCraft is excellent. They are reliable and prompt. Their customer service is always friendly and informative too”.

“We have been using GableCraft now for a number of years and have had a great service throughout. The quality has been really good. I would definitely recommend them.

“GableCraft is a fantastic company to deal with and has excellent customer care. Would not use anyone else for our gable and end frames!”

“I have always had a service from GableCraft that excels in this industry and that is why we use them for all are shaped frames.”

“I have been using GableCraft for the last 6 years and they are, hands down one of the best suppliers I use. Can`t put it more simply.”

Contact us...

Address

GableCraft Ltd

Unit 4A

Harpings Road

Hull

East Yorkshire

HU5 4JF

Phone

01482 876680

admin@GableCraft.co.uk